(Currently Out of Stock)

EC-10 Trim Shear Features

- Powerful, pistol grip reversible motor

- Designed for specialized heavy trimming work

- Because of its weight, this tool is best suited for bench or vise mounting, but is equally suited as a portable tool

- The power unit in the EC-10 trim shear is basically the same as in the EC-9, except that the cutter housing, gears, and cutter shafts are increased in size for added strength and durability

- Feed and roll cutters manufactured from special tool steel, hardened and ground for long life

EC-10 Trim Shear Models and Specifications

EC-10 PR *

- Mild Steel Capacity – Up to 0.080 Inconel

- Feed – Approximately 3 1/2 feet/minute

- Throat Capacity – 2 inches

- Weight – 19 pounds

- Length – 12 1/8 inches

- Height – 7 3/8 inches

- Width – 5 inches

- Minimum Hose Size – 3/8 inch

* P = Pistol Grip Motor R = Reversible Motor

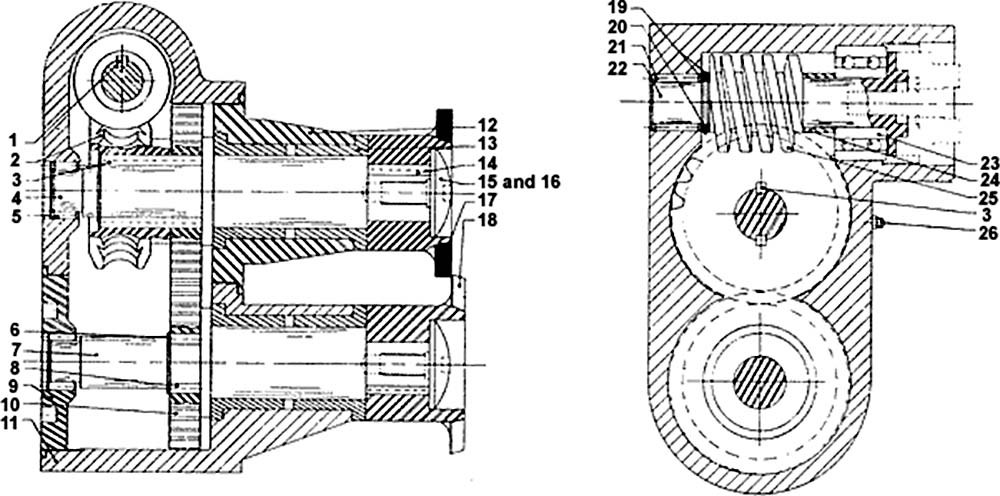

EC-10 Product Illustration

Click diagram to enlarge

EC-10 Trim Shear Parts List

Index, Part #, Description, Quantity

1 - EC 9211 Worm Key, 1

2 - EC 9924 Worm Wheel, 1

3 - EC 9286 Worm Wheel Key, 2

4 - EC 9921 Feed Cutter Shaft, 1

5 - EC 9963 Cutter Shaft Needle Bearing, 2

6 - EC 9962 Cutter Shaft Retainer Ring, 2

7 - EC 9922 Roll Cutter Shaft, 1

8 - EC 9240 Cutter Shaft Key, 2

9 - EC 9919 Cover (Rear), 1

10 - EC 9923 Spur Gear, 2

11 - EC 9916 Housing, 1

12 - EC 9920 Cover (Front), 1

13 - EC 9918 Shaft Bushing, 4

14 - EC 9068 Key (Feed & Roll Cutter), 4

15 - EC 9917 Cap Screw Washer, 1

16 - EC 9288 Cap Screw, 2

17 - EC 9915 Feed Cutter, 1

18 - EC 9914 Roll Cutter, 1

19 - EC 9351 Thrust Bearing *, 1

20 - Not Used

21 - EC 9307 Drive Shaft Needle Bearing, 1

22 - EC 9276 Drive Shaft, 1

23 - EC 9309 Drive Shaft Bearing, 1

24 - EC 9290 Worm Spacer, 1

25 - EC 9350 Worm, 1

26 - EC 3312 Grease Fitting, 1

*Older models used Retainer Rings EC 3791 and two (2) Worm Retainer Spacer EC 9217 instead of Thrust Bearing EC 9351

EC-10 Trim Shear Service & Maintenance Instructions

Operation:

The tool is designed to operate on 90 PSI air pressure using a 3/8 inch hose up to 8 feet in length. If additional hose is required, a 1/2 inch or larger hose should be connected to the 3/8 inch hose.

Lubrication:

An automatic in-line filter lubricator is highly recommended to increase tool life as well as keeping the tool in sustained operation. If in-line lubricator is not used, the tool should be lubricated several times daily by disconnecting the air hose and injecting a few drops of a high grade No. 10W machine oil in the air inlet.

Product Safety Warnings

For your safety, make sure you apply standard shop practices at all times when using this tool. Your failure to apply these practices may result in serious bodily injury.

Protect your eyes, ears, and other parts of your body by using safety equipment - respirator, safety goggles, ear mufflers and other necessary safety devices - at all times when operating this tool or when you are in the area where this tool is being operated.

For maximum stability and safety, only operate these tools with both hands on the tool. Follow the cutting tool manufacturer’s mounting and operating instructions and avoid any direct contact with the sharp cutting edges of the tool.

Modification or improper use of this tool, including, but not limited to, removing guards, mufflers, or other safety devices, voids all responsibilities of the manufacturer.

Excessive air pressure, over and above 90 PSI, will increase the RPM, the sound level, and can be a damaging factor to both the operator and the tool.

Stay alert! Watch what you are doing! Do not operates this tool when under the influence of medication, alcohol, or drugs!

Disconnect the air supply before changing the cutter and whenever making adjustments or repairs.

Do not remove warning tags until both sides have been read and understood by the person(s) responsible for safety in your plant.

If you need any other information, consult your supervisor or contact:

EC Eng. & Mfg., Inc.

P.O. Box 1090

Mountain Home, AR 72654-1090

Phone: (870) 425-3979

Fax: (870) 424-2228

Email: info@ecengmfg.com